January

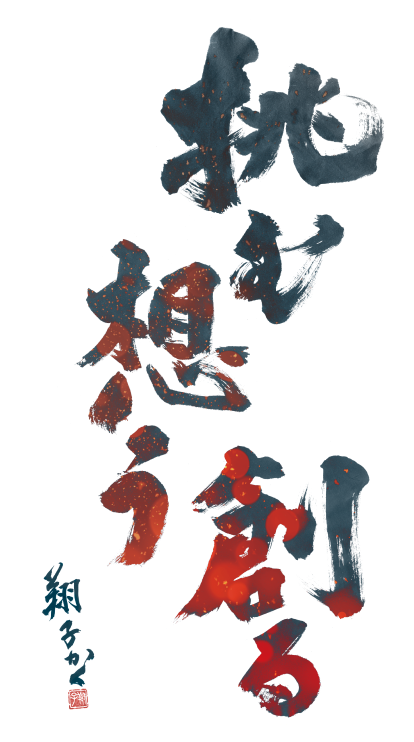

Challenge, Think, Create

Yahiko Fujimori the founder once said, “Originality is born by challenging the difficult and unknown.” Even in situations when things didn’t go as planned, he disliked easy or lazy mimicking and developed new products that were not available in the market with a spirit of “Where there is a will, there is a way,” and went on to promote sales himself. The phrase Yahiko left and the spirit in it has been passed down unbroken by all employees even after a hundred years.

Desktop Wallpaper DownloadFor further details, place the cursor over each individual image.

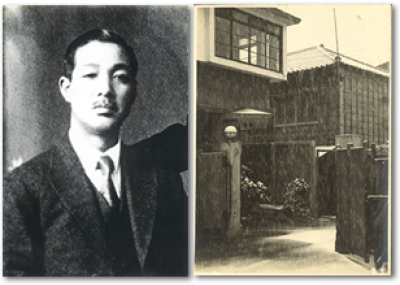

1913

Yahiko Fujimori opened a pilot plant (Osaki Plant) at his home, where he started to develop packaging materials to protect silk products during overseas transportation from damage caused by rain, wind and salt

1914

Fujimori Kogyosho (Head Office: Osaki-cho, Ebara-gun, Tokyo) established as a limited partnership, with Yahiko Fujimori appointed President

Founding

Fujimori Kogyosho was established as a limited stock company in 1914. The company's founder, Yahiko Fujimori, immersed himself in the development of packaging materials capable of protecting cotton and silk thread products, typical exports of Japan at the time, from damage by wind, rain, and salt during transport. He succeeded in the development of moisture-proof, waterproof Tarpaulin Paper using the Fujimori method of special waterproof coating under patents. This marked the origins of the company's DNA, which contributes to society through the creation of unique value.

Sales of moisture-proof and waterproof tarpaulin paper, processed with Fujimori-type special waterproof paint, started

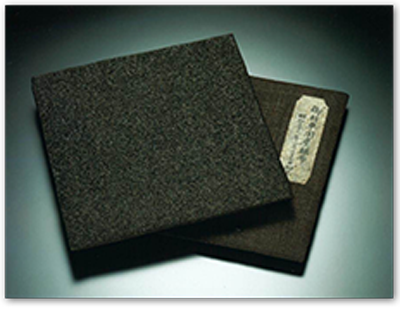

Moisture-proof and waterproof paper : Tarpaulin Paper

Devoting himself to the development of moisture-proof and waterproof paper, in 1914 Yahiko Fujimori developed and delivered a processed paper called Tarpaulin Paper, which runs embroidery thread between layers of paper. Tarpaulin Paper, which boasted "no wetness, no moisture" as packaging for yarn and fabric exports, was awarded patent rights and laid the foundation for the company's business at the time.

Start of World War I

1915

Trade with European countries was suspended, which resulted in huge inventories

DevelopedYamato ShikigamiandTaisho Kamimushirobut with poor results. Sales ofBanzaigutsumade of waterproof cloth were also not successful

1918

Spanish Flu pandemic

End of World War I

1920

Postwar depression

League of Nations started. Japan joined as permanent member

1921

Waterproof cloth to cover the roofs of passenger cars made of tarpaulin paper was developed, employed by the Ministry of Railways and also used for imperial cars

Waterproof cloth for covering the roofs of passenger cars

Waterproof roofing fabric for railway carriages, made with Fujimori-method special waterproof coating, was adopted by the Ministry of Railways. Achieving stable quality initially took time, but successive improvements were made and the product was adopted as a waterproof fabric for railway carriages for a long time following the war. It was also used in vehicles for the Imperial family.

1923

Yamato ShikigamiandTaisho Kamimushirorapidly started to sell as a replacement roof material for galvanized sheet iron

Great Kanto Earthquake

February

Shuhari, Three Stages of Mastery

Yahiko Fujimori built the foundation of a business but met his untimely death at the age of 51. This phrase by Fuhaku Kawakami, a master of the tea ceremony in the Edo period, is chosen to represent the “守” (protecting tradition) spirit of Misaho Fujimori, Yahiko’s wife who promised to protect Fujimori Kogyo that they had developed together, the “破” (breaking with tradition) concept by Chutaro Mugikura who developed the business with sound management that “cherishes even the thoughts of a person who just made ropes in the factory” and exploring new sales channels and the “離” (creating one’s own techniques) commitment of those who created unique products.

Desktop Wallpaper Download1924

Second Movement to Protect the Constitution

1925

Universal Manhood Suffrage Law passed

1926

Tarpaulin paper composed of two sheets of craft paper applied to wallpaper for homes, and utility model rights granted

Era name changed to Showa

1927

Yahiko Fujimori, President, suddenly passed away. Misaho Fujimori took charge of management, succeeding the position of her late husband. Chutaro Mugikura appointed General Manager

Showa Financial Crisis

1928

Tarpaulin paper applied to moisture-proof paper for nitrogenous lime fertilizer bags

1929

Great Depression

1931

Tarpaulin paper applied to cocoon bags and moisture-proof paper for tea

Manchurian Incident occurred

1933

Japan withdrew from League of Nations

March

High in the Sky, a Great Wind

This phrase was written on a kite by Zen Master Ryokan when he was asked by a child. This was a time when people lived eagerly, asking themselves questions such as what they could do and what they should protect if a great wind shook the entire world. Fujimori Kogyo has a history that was stimulated by a great wind called war, and the company was inclining increasingly towards military demand. Those were the days when it was necessary to have a strong resolution to live with all-out efforts in spite of a lot of inconsistencies.

Desktop Wallpaper DownloadFor further details, place the cursor over each individual image.

1934

Japanese government gave formal notice of termination of Washington Naval Treaty to the U.S.A.

1935

Hideki Yukawa published his theory on mesons inJournal of the Physico-Mathematical Society of Japan

1936

February 26 Incident

Reorganized as Fujimori Kogyosho, Ltd., and Yaguchi Plant opened

1937

Toshihiko Fujimori appointed Plant Chief and Head of Laboratory

Neoloid paper that is moisture-proof protein-based paper for tobacco, pharmaceuticals, gunpowder, etc. developed

Sino-Japanese War began

1938

National Mobilization Law promulgated

1939

Start of World War II

1940

Moisture-proof inner boxes for ammunition made out of tarpaulin paper developed and adopted by Japanese Imperial Army as standard

Chutaro Mugikura, Executive Director, appointed Representative Director

1941

Shoa Kako K.K. established at Yaguchi Plant. Toshihiko Fujimori appointed Executive Director

Start of Pacific War

1942

Nagatsuda Plant opened

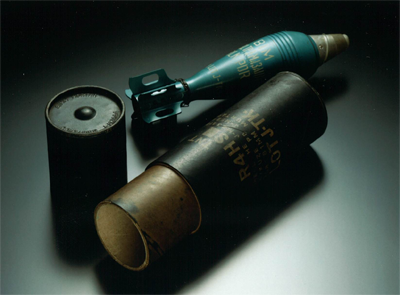

Moisture-proof tubes for artillery shells developed

Moisture-Proof Cylinders for Artillery Shells

In the autumn of 1939, the Army Technical Research Institute asked the company to manufacture moisture-proof inner casings for ammunition. The company developed a solution using Tarpaulin Paper and asphalt as the adhesive. Following improvement into a cylindrical form, the product was subsequently adopted as moisture-proof cylinders for artillery shells, achieving enhanced transport efficiency by alleviating the need for sturdy wooden boxes.

Michihiko Fujimori appointed Director

1943

Toshihiko Fujimori appointed Representative and Executive Director

Senzoku Research Laboratory opened

Damper oil for aircraft engine boost controller, Belovisol, developed

April

Training again and again to become a fine person

As iron repeatedly forged becomes strong steel, Fujimori Kogyo has overcome a myriad of hardships and grappled with difficult challenges over and over, thereby developing its corporate strengths. By taking advantage of the technologies that had been developed through the manufacturing of tarpaulin paper as well as those developed during the war but not commercialized, we entered the field of architectural materials during the postwar turmoil and established a firm position, thanks to products such as ASTILE, whose business had drastically expanded, which was driven by the special procurement boom.

Desktop Wallpaper DownloadFor further details, place the cursor over each individual image.

1944

Corporate name changed to Fujimori Kogyo Co., Ltd., and Shizuoka Plant opened

Shizuoka Plant

In preparation for air raids against the Tokyo metropolitan area, in January of 1944 we signed a land lease agreement for 16,838㎡ in Sunto-gun, Shizuoka Prefecture (currently Ootsuka in the city of Numazu). We completed construction of the Shizuoka Plant in July of the same year and began manufacturing Tarpaulin Paper and waterproof roofing fabric for vehicles.

1945

Hirohiko Fujimori appointed Director

Osaki Plant, Yaguchi Plant and Senzoku Research Laboratory destroyed in air raids. Planned construction of a large farm as a site for employees to evacuate to

End of World War II

1946

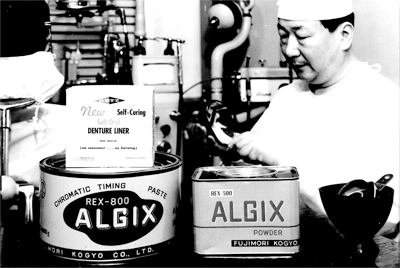

Acrylic resin-based denture and baseplate material, Rexin, developed

Rexin denture base material

Drawing on technology developed by the Senzoku Research Laboratory during the war, the company embarked upon the development of resin- and monomer-based denture materials. It commercialized the denture base material Rexin, made with acrylic resin, in 1946, and the denture rebase material Permanent Liner and the elastic denture mold removal material ALGIX in 1948. This product became popularized to the point that relevant parties equated the name "ALGIX" with dental impression (molding) material.

Priority production system employed by Japanese government towards the reconstruction of industry

1947

Kawasaki Plant opened

Kawasaki Plant

Having lost our Osaki Plant during the war, building a production base in the Kanto area was an urgent issue for the Company's management. A search for a site in the Tokyo metropolitan area resulted in the acquisition of about 10,000㎡ of land and buildings on the former plant grounds of a three-wheeled automobile manufacturer in the city of Kawasaki. We renovated the building interior and opened the Kawasaki Plant in November of 1947.

1948

Waterproofing seal materials, LEXILITEPUTTY, developed

1949

Asphalt tiles, Astile, developed and adopted as materials for barracks and floors in U.S. military bases

Astile

In development aimed at the field of construction materials, the company applied the asphalt-related technologies and know-how it had built up in the manufacture of Tarpaulin Paper to engage in the development of asphalt tiling. Kneading filler, asphalt, and pigment into tiles with a thickness of 3.2 to 4.8 mm and a size of 9 to 12 inches square, it produced and sold the product under the name "Astile."

Osaka Office opened

High performance moisture-proof and waterproof paper, BARRIER METAL FOIL, developed

BARRIER METAL FOIL

In 1949, the company developed BARRIER METAL FOIL, a packaging material for mechanical parts that require high moisture resistance. It began delivering the product to U.S. military-related customers. The material is composed of aluminum foil on Tarpaulin Paper, with a surface coating of polyvinyl butyral. Aluminum foil was difficult to obtain during this time of materials shortages, and was easily wrinkled in the bonding process. Through trial and error, the company arrived at a method that neatly bonded the foil.

1950

Start of Korean War

1951

Fujimori Kenzai Co., Ltd. founded. Michihiko Fujimori appointed Executive Director

Domestic sales of Astile started

Import of polyethylene (by high pressure method) started

1952

Mass production of Fiber Container for artillery shells started

Yayoi Shoji Co., Ltd. established

1953

Vaporizable corrosion inhibitor, NITRA, developed

Japan’s first self-service supermarket opened by Kinokuniya

May

Beyond

These were times when we focused on R&D with a commitment to “creating something beyond tarpaulin paper, not something to replace it,” which had been succeeded and developed ever since the foundation of the company. Toshihiko Fujimori, Senior Vice President, paid attention to polyethylene, imported a polyethylene laminator that was not available in Japan and at the same time promoted in-house development of polyethylene-based wrapping. With POLYWRAP, Fujimori Kogyo thus developed the field of food packaging where the mainstream used to be cans. In addition, with the commercialization of BYNASHEET, the company expanded its range of development to functional products beyond packaging.

Desktop Wallpaper DownloadFor further details, place the cursor over each individual image.

1954

40th anniversary of founding

Celebration of 40th Anniversary of Founding Hakone Sanmaiso

Head Office moved to Nihonbashitori

Japan Polyethylene Products Industry Association founded

1955

Packaging materials for Kao Feather Shampoo developed jointly with KAO Sekken K.K. (current Kao Corporation)

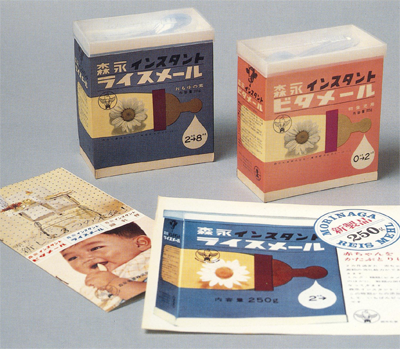

Packaging for Kao Feather shampoo

Based on the aluminum foil processing technology developed for BARRIER METAL FOIL, the company developed packaging materials for Feather Shampoo in collaboration with Kao Soap Company. This was a moisture-proof packaging material featuring an aluminum foil surface worked with gravure printing. Its shiny appearance in stores give it a powerful appeal that made it a hit product. This product spurred the company to tackle the flexible packaging products offered today.

Polyethylene laminator developed in house (produced for first time in Japan)

1956

POLYWRAP polyethylene processed paper developed, expanding the business to food packaging material field

Polyethylene laminate : POLYWRAP

In 1956, the company became the first company in Japan to introduce a polyethylene laminator from the U.S. and began manufacturing POLYWRAP polyethylene laminated paper. This product was initially composed of paper plus polyethylene, and aluminum foil plus polyethylene. To meet food application needs, however, the transparent material cellophane came to be heavily used as the base material, leading to the later development of POLYCELLO SPZ.

Development of Fuji Tube Fuji Void formwork material for construction and civil engineering

FUJITUBE, FUJIVOID

These products are a wound-type construction formwork material made with Tarpaulin Paper and the application of ammunition shell container technology. Winning acceptance for their ease of handling in construction work and their water resistance following construction, the products established a firm position in the construction industry. They further rode the building boom during Japan's period of high economic growth to become a pillar of the company's revenue at the time.

Japan joined United Nations

1957

Head Office moved to Kanda-Higashiimagawacho

Nikka Gravia Co., Ltd. established under a basic principle of widely promoting POLYWRAP with gravure printing

Airtight paper boxes ECOPACK combining POLYWRAP and paper bag developed

ECO PACK

Advancing development of an airtight paper box that combined Polywrap with paper cartons, the company commercialized the ECO PACK moisture-proof carton. It designed and manufactured its own box-forming machinery and filling machinery and sold these as a set combined with packaging materials, finding use in the production of toothpaste, skim milk, and other products.

1958

Kyushu Office opened

Tokyo Tower completed

1959

New laboratory established at Kawasaki Plant

SPZ poly cellophane for vacuum packaging and boil sterilization commercialized

POLYCELLO SPZ

At the time this product was developed, miso paste was mainly sold by weight at shops. However, the advance of supermarkets boosted the need for nationwide distribution and long-term preservation, issues that miso producers struggled to address. The company's POLYCELLO SPZ packaging material, featuring outstanding resistance to boiling, protection from air, and toughness, maintained the delicate flavor of miso and contributed to achieving rich diets.

1960

Osaka Plant opened

Silicone-based release paper, BYNA SHEET, developed and started to be manufactured

Release paper : BYNA SHEET

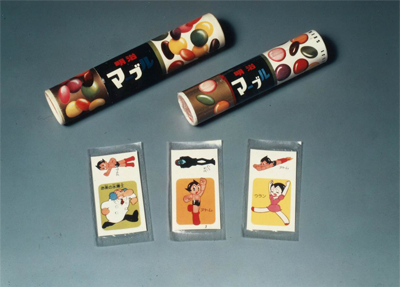

In 1960, the company's development of industrial materials yielded the silicone-coated release paper BYNA SHEET. Adhesive products using release paper had begun to see use in a variety of fields, but what made BYNA SHEET popular at the time was "patch stickers" offered as freebie prizes inside chocolate confectioneries.

Start of Vietnam War

1961

Osaka Office promoted to Sales Office

First successful crewed spaceflight by Soviet Union

1962

Toshihiko Fujimori appointed President

Technical collaboration agreement with Tetra Pak (Sweden)

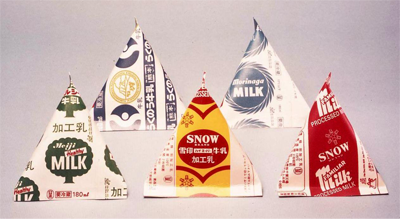

Tetra Pak

The 1960s were a time of calls for greater efficiency in distribution. Containers for liquids underwent a shift from bottles and cans to light, safe paper and resin containers. Against this background, the company set its sights on the development of liquid containers, focusing on the milk containers manufactured and sold by Tetra Pak in Sweden. The company signed a technical tie-up agreement with Tetra Pak in 1962 and began manufacturing and selling Tetra Pak paper the following year.

1963

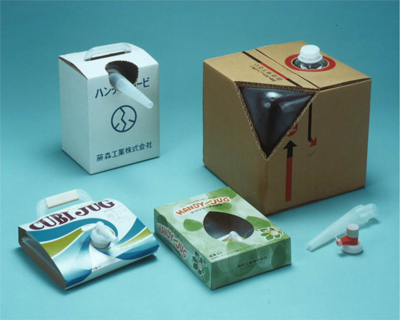

Technical licensing agreement with Hedwin Corporation (U.S.A.) for CUBITAINER foldable plastic liquid containers

Manufacturing and sales of Tetra Classic container paper started

BYNASHEET employed in the Astro Boy sticker that was given as a bonus gift by Meiji Seika Kaisha, Ltd. (current Meiji Seika Pharma Co., Ltd.)

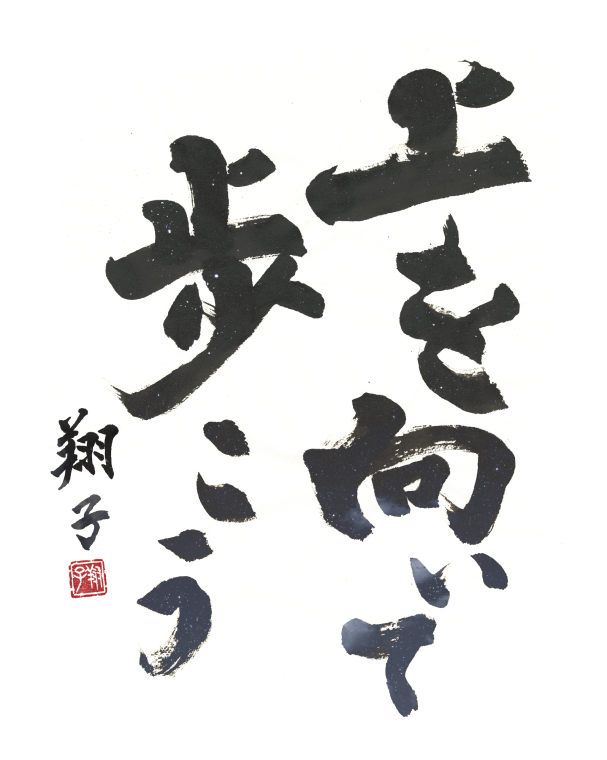

June

Let’s walk while looking at the sky above

This was a period when, by riding the wave of high economic growth, Fujimori Kogyo addressed challenges one after another and moved forward while also repeating failures. At the early stage of manufacturing, Cubitainer, SPZ and retort pouch packaging for Bon Curry underwent many faults, but we learned so much from these failures and achieved market shares in different fields. In addition, with the full-scale export of HI-PY as a turning point, Fujimori Kogyo established an overseas local company at the earliest stage among Japanese companies in spite of uncertainty.

Desktop Wallpaper DownloadFor further details, place the cursor over each individual image.

1964

50th anniversary

Celebration of 50th Anniversary of Founding

To note the 50th anniversary of our founding, we held commemorative ceremonies and celebrations in the Kanto and Kansai areas. We looked back on the half century of the Company's history, renewed our determination to attain our next stage, and vowed to achieve further advances as a united company.

Manufacturing of CUBITAINER started

Cubitainer

Pushing ahead with the development of liquid containers, in March 1963 the company signed a technical tie-up agreement with U.S.-based Hedwin Corporation for its CUBITAINER foldable plastic liquid containers, and began manufacturing the product at the Kawasaki Plant in April of the following year. The company highlighted the convenience of one-way containers as replacements for the then-mainstream earthenware and other containers, and broadened the use of one-way containers to encompass vinegar, sake, industrial chemicals, and more.

Tokyo 1964 Olympic Games held

1965

Head Office moved to Kanda-Iwamotocho

Sales of HI-PY plastic cloth sheets started

HI-PY

HI-PY, a polyethylene-laminated sheet of polyethylene oriented yarn fabric, was highly regarded as a product with water resistance and toughness not offered by bags of hemp or other conventional packaging materials. Growing demand for HI-PY led to the construction of the Ohama Plant (currently the Kakegawa Workplace).

Showa 40 (1965) recession and Izanagi boom

1966

Production of flexible package type laminator, BISWRAP, started

BISWRAP

In May 1966, the company introduced a dry laminator from Germany and began manufacturing BISWRAP, a flexible package-type laminated film. BISWRAP allowed the company to meet diverse needs, and was even adopted as packaging material for the retort-pack curry products that had just entered distribution at the time.

Licensing agreement with Thimonnier & Cie (France) to produce DOYPACK self-standing plastic film bags

1967

Japan’s first self-standing pouches, DOYPACK, commercialized

DOYPACK

In 1967, the company signed a technical tie-up with France-based Thimonnier Company and began manufacturing DOYPACK, Japan's first free-standing plastic film bag. This product offered greater logistics efficiency than metal tubes and glass containers, and garnered attention for the improved display effect of the pouch's self-standing capability. The product came to play a part in expanding the applications for flexible packaging materials, including for fruits, preserved seafoods, miso, and wild vegetables. The product later took the world by storm as the DSD package for soft drinks (1980).

European Community (EC) established with six nations

1968

Fujimori Kenzai Co., Ltd. and Yayoi Shoji Co., Ltd. merged to form Fujimori Sangyo Co., Ltd.

Retort pouch packaging materials developed and used in the first retort pouch bags for Bon Curry of Otsuka Foods Industry Co., Ltd. (current Otsuka Foods Co., Ltd.)

1969

Full-scale export of HI-PY and Overseas Business Division established

First human landing on the moon by the U.S.A.

1970

Head Office moved to Nihonbashi-Bakurocho, and Ohama Plant opened

Ohama Plant

The Ohama Plant (currently the Kakegawa Workplace) was built in the town of Ohama in Ogasawara-gun, Shizuoka Prefecture. Production of HI-PY (a sheet used for rain cover used in construction and civil engineering) was transferred to the new plant from the Kawasaki Plant.

Slip sheets for cassette tapes, SMOOPER, commercialized by using BYNASHEET

Japan World Exposition Osaka 1970 held

1971

Joint venture companies Fujimori Plastic Industries (Malaysia), Thaishin Kogyo (Taiwan) and Shinshin Jitsugyo (Taiwan) established

1972

Nikka Gravia Co., Ltd. merged with Yayoi Kogyo Co., Ltd., changing the corporate name to Nikka Co., Ltd.

Sapporo 1972 Winter Olympic Games held

1973

Japanese spelling of Fujimori Sangyo Co., Ltd. changed. Kyushu Office promoted to Sales Office and a basic research laboratory established

FROMASHEET, packaging material for rectangular parallelepiped process cheese, developed

First Oil Crisis

July

Living together

This was a period when Fujimori Kogyo, which had lost its founder too early, expanded the business to fields that lead to “living” such as pharmaceuticals and medicine. Under the guidance and advice of pharmaceutical manufacturers, the Nabari Plant was built to be compliant with GMP (Good Manufacturing Practice). This management decision in consideration of the future, in spite of concerns about overperformance, was unwavering and became a great asset for the future.

Desktop Wallpaper DownloadFor further details, place the cursor over each individual image.

1974

Osaka Sales Office promoted to Osaka Branch. SCR International (Hong Kong) and MAPLEC (Brazil) established

V-Type, MEDDIC packaging material for gas sterilization, developed

Began sales of Meatlonn packaging material for meat processing

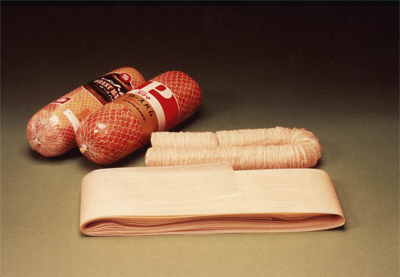

Meatlonn

Roast ham and boneless ham are prepared by pushing a portion of meat into a special paper-based packaging material and smoking the meat. As this special packaging material required the strength to shape the ham while allowing smoke and moisture to pass through, its development was particularly difficult. The company solved the problem by combining viscose, a raw material of cellophane, with paper made from hemp, and launched sales of the resulting product under the name Meatlonn in 1974.

1975

Malaysia Packaging Industry Sdn. Bhd. (Malaysia), a joint venture with Ajinomoto Co., Inc., established

End of Vietnam War

1976

Osaka Plant closed with the transfer of operations to Nabari Plant towards GMP certification. Nikka Co., Ltd. became a subsidiary

Nabari Plant

As orders for medical instrument packaging materials surged in volume in the 1970s, we planned the construction of a new plant to replace the aging Osaka Plant. In November of 1974, we secured approximately 19,000㎡ of land in Kuramochi Industrial Park in the city of Nabari in Mie Prefecture. We established policies to create a new plant with a clean environment and a manufacturing management standards system unmatchable by any competitor for a decade. We constructed the Nabari Plant in compliance with GMP standards, a first in Japan for the manufacture of packaging materials.

MEDDIC, packaging material for medical equipment, developed

MEDDIC

As medical instruments are sterilized with ethylene oxide gas (EOG) after packaging, the packaging material must allow permeation by the gas without infiltration by bacteria. Drawing on the sterilization technology developed for retort packaging materials and other applications, the company undertook the development of packaging materials for medical instruments. The result was the MEDDIC sterilization packaging material for gas sterilization, made with polyethylene non-woven textile tape in the sealing component.

1977

Fujimori Sangyo Co., Ltd. became a subsidiary

Multipurpose high-precision test coating machine (MP machine) introduced at Kawasaki Plant

Representative Office opened in New York to promote sales of HI-PY

1978

UBF (M) became the first Japanese retort pouch to receive FDA (U.S. Food and Drug Administration) approval

Treaty of Peace and Friendship Between Japan and China concluded

1979

Sunforest International (U.S.A.) established for the purpose of full-scale advancement into the American market

Started to manufacture FILMBYNA release film and developed Laminated Tube

FILMBYNA

This release film is coated with release agents such as silicone resin, for use with various plastic products and composite films. In the latter half of the 1970s, it found use as a sliding film for cassette tapes, along with wide use in areas including the automotive industry and transdermal patches. The film is still used in the company's own adhesive products as well as in outside sales.

Film for laminated tubes

This aluminum foil-containing, multi-layer laminated film was developed in 1979. The tube material won highly regard for its outstanding shape restorability that allows fully using up the contained product. It still enjoys wide use as a packaging material for products such as toothpaste.

Second Oil Crisis

1980

Aseptic filling technology-based packaging equipment developed

Manufacturing and sales of DSD DOYPACK for soft drinks and its packaging system started

Start of Iran-Iraq War

1981

MO Sheet for organic semiconductors and TOUGHWRAP packaging material for small liquid bags developed

Space Shuttle Columbia launched from Kennedy Space Center by National Aeronautics and Space Administration (NASA)

1982

Technical collaboration with Bosch (West Germany) for automated aseptic packaging system

DSD adopted for Capri-Sonne by Ezaki Glico Co., Ltd. as a packaging material

FF SHEET, waterproof sheet for tunnel construction work, developed

FF SHEET

Demand for tunnel construction grew in line with the development of railways and highway networks, the excavation of undersea tunnels, and the expansion of sewer systems. The greatest challenge in this construction was completely blocking off inflow water from the inner walls of tunnels. In response to this, the FF Sheet waterproof sheet for tunnels was developed and commercialized, along with proposals for construction work methods using the sheet.

1983

Pharmaceutical solution bags developed

Tokyo Disneyland opened

August

Storm puts strong grass to the test

The phrase means “finding strong grass that does not break even in fierce winds” or “difficulties identifying one’s strengths.” The Numata Plant that was built with a sense of mission to contribute to the advanced information society has a history where, with deficits for seven consecutive years since the start of operation, employees continued weeding while talking about their dreams to each other. The spirit inherited in Fujimori Kogyo, to consider difficulties interesting, not hardships, that is to say, its strength like weeds, would later lead Fujimori Kogyo in a new age.

Desktop Wallpaper DownloadFor further details, place the cursor over each individual image.

1984

VA (Value Analysis) Committee established

Automated aseptic packaging system developed

1985

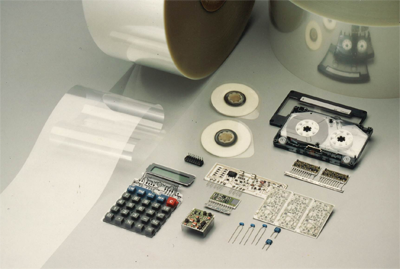

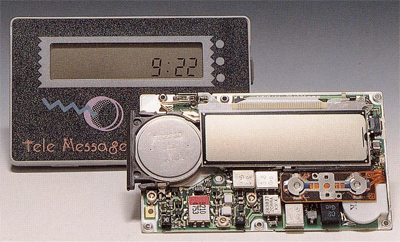

Sealed pack material, Pouch Film, developed based on request from Meiko Shokai Co., Ltd.

Manufacturing of NEW TOUGHWRAP packaging material for small liquid bags started

NEW TOUGHWRAP

The company developed TOUGHWRAP, a wrap with greater strength than existing small bag packaging materials for liquids, and began manufacturing the product in April 1981. Following further improvements, in 1985 the company launched NEW TOUGHWRAP that combined strength with ease of filling, to high acclaim from customers.

Plaza Accord

1986

Policy management and functional qualification systems introduced. NewDUP (new demand, use and product pursuit) movement launched

Equal Employment Opportunity Act enforced

1987

A-21 Project launched towards the preparation of the 1st medium-term management plan

AMOREX film for LCDs developed, expanding the business to information electronics field

AMOREX

This plastic film for LCD substrates was developed in 1987. Glass is used even now as the substrate for LCDs, but in response to the pre-existing need for lighter, thinner, and more flexible substrates for the portable information devices that began to appear around the time, the company leveraged its precision coating technologies, layering technologies, and materials technologies to develop AMOREX. This development subsequently led to the advancement of the company's current information and electronics business.

Division and privatization of Japanese National Railways

1988

As part of the 75th anniversary project, research laboratory building with experiment factory constructed

Development of film for pressed flower telegrams

Pressed flower telegram film

This film, jointly developed with Nippon Soda Co., Ltd., protectively covers flowers pressed into telegram mounting. The novel idea of adding literal pressed flowers to telegrams, which until then were merely a means of sending text messages, found great acceptance.

End of Iran-Iraq War

1989

IV bags for aseptic filling developed

IV bags for aseptic filling developed

As medical malpractice and a growing burden on medical workers became social issues in an increasingly aged society, many problems were pointed out in the glass bottles used for of intravenous infusion solution in hospitals, including their weight and bulk, accidents caused by breakage, generation of medical waste, and the incidental hazard of nosocomial infection. In response, the company began manufacturing plastic film soft bags in collaboration with U.S.-based Baxter.

Era name changed to Heisei

Consumption tax introduced at a rate of 3%

1990

New Corporate Vision, Management Policy and Code of Conduct established heralding “The Creation of ‘TSUTSUMU VALUE’”

New R&D HQ established

1991

Akihiko Fujimori appointed President

Division and flex-time systems introduced

Development of HI-CARRY large flexible container

HI-CARRY

This large flexible container was developed in 1991. The rolls used in making HI-CARRY are an advanced and improved version of HI-PY, manufactured from materials with higher strength. HI-CARRY's widespread applications included transport and storage of plastic resins and other raw materials, as well as transport containers for industrial chemicals, foods, fertilizers, and more.

Collapse of bubble economy

1992

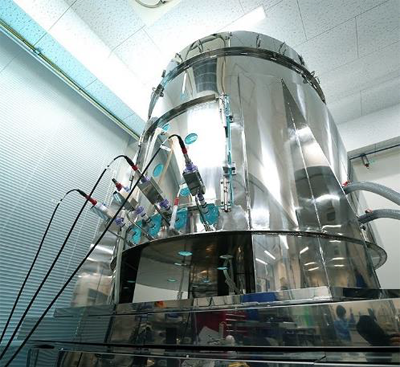

Numata Plant opened

Numata Plant

In the mid-1980s, our core business lay in the field of light packaging for foods, pharmaceuticals, and other products, with sales in this business accounting for over 60% of total sales. However, the market in this field appeared to be mature. In response, within the rapidly growing electrical and electronic industry, we set our sights on the new business of information equipment. We established a policy of full-scale entry into the manufacture of functional materials used in this field, and in May of 1992, constructed a plant featuring a Class 100 high-clean precision coating facility in the city of Numata in Gunma Prefecture.

United Nations Conference on Environment and Development (Earth Summit) held in Brazil

1993

Awarded Kinoshita Prize by Japan Packaging Institute

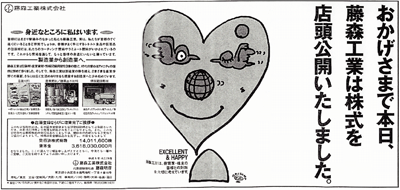

Shares offered publicly on the OTC market

Shares offered publicly on the OTC market

September

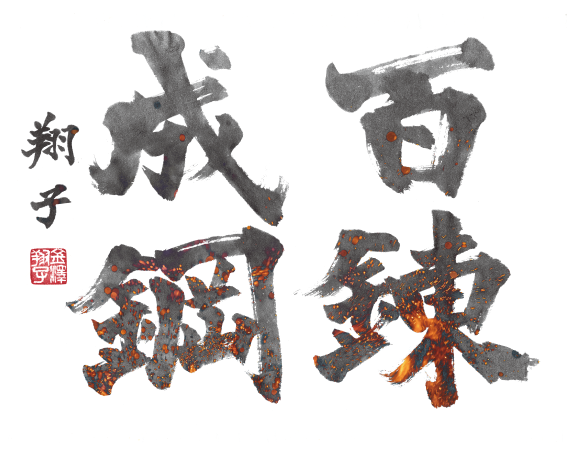

Z logo

In 1994, which was the 80th anniversary, Fujimori Kogyo established a brand name conscious of making inroads into global business, ZACROS. The name was formed from a combination of the letter “Z,” which represents the ultimate and the unknown, and “ACRO,” which means the topmost or forefront in Greek. This reflects the desire to be a company that always looks towards the future and continues to explore new possibilities. The logo is designed as “Z,” which is compared to a lamination layer, while the blue and green lines represent the vast expansion of a clear blue sky and the strength of a never-ending green earth, respectively.

Desktop Wallpaper DownloadFor further details, place the cursor over each individual image.

1994

Celebrating the 80th anniversary, brand name, ZACROS, adopted

ZACROS

We established the name "ZACROS" with the aim of changing the corporate name that would represent our business. At the same time, we codified our founding spirit that has been inherited without break through our predecessors, and established the corporate philosophy "We will contribute to the achievement of a comfortable society through the creation of 'wrapping value'." This "creation of 'wrapping value'" carries the meaning of "imbuing materials with life through functionality," doing so through our unique technologies for compositing and layering. It also incorporates our wish to create value that brings fun, comfort, security, and dreams to people's lives ("wrapping value").

Nikka Co., Ltd. and Kyowa Kogyo Co., Ltd. merged and changed tradename to Fujimori PlaChemical Co., Ltd.

SCE (current Sony Interactive Entertainment Inc.) launched first-generation PlayStation

1995

Miyagi Optodevice Co., Ltd. established

ZACROS Quality Code established

Containers and Packaging Recycling Law enacted

1996

THAI FPC CO., LTD. established with investment by Fujimori PlaChemical Co., Ltd.

THAI FPC CO., LTD.

We established THAI FPC CO., LTD. in the Bangpa-in Industrial Estate on the outskirts of Bangkok. In March of 1997, we completed the first manufacturing plant in Thailand with a clean environment aimed at GMP compliance. With state-of-the-art slitters, bag-making machinery, and flexo printing machinery, the plant began manufacturing medical packaging materials for artificial dialysis and other applications, supplying products throughout Southeast Asia.

Concluded contract for shape patent of FLOWPACK with CELLPACK (Switzerland)

Development of MASTACK TFB surface protection film

MASTACK TFB

This surface protection film is made with PET film developed to protect polarizing plates used in liquid crystal displays. It is also used today in applications including optical films. This product group, which has undergone repeated improvements to capture changes in the market, has grown into a current mainstay business of the company.

1997

Development of PP-mono-PTP (Press Through Pack) to address dioxins and other environmental problems

PP-mono-PTP (Press Through Pack)

Pharmaceuticals such as tablets and capsules use vinyl chloride for the transparent bottom material and PTP made with aluminum foil for the lid material of containers. To address environmental problems including dioxin, which was coming under attention at the time, the company developed PP-mono-PTP that employs a single polypropylene material as both bottom and lid materials.

Self-standing refill pouches, FLOWPACK, developed

FLOWPACK

Amid increasing awareness over global warming and other environmental issues, as exemplified by the enactment of the Containers and Packaging Recycling Act in 1995, the company began selling FLOWPACK in 1997. FLOWPACK, a refill pouch with pouring tube inserted, was adopted in household detergents to make refilling easy. Since then, FLOWPACK's applications have expanded to encompass hair care and other products, and it has become a mainstay product in the company's packaging business.

Consumption tax rate increased to 5%

1998

Nagano 1998 Winter Olympic Games held

1998 FIFA World Cup France held, first time for Japan to participate

2000

Z-TAINER self-standing film-lined liquid container launched

Kyushu-Okinawa Summit held

2001

September 11 attacks took place

Apple Inc. (U.S.A.) launched iPod

Development of PASS dual-layer structure aerosol system

PASS dual-layer structure aerosol system

The Pouch Aerosol Spray System (PASS) developed in 2001 is an aerosol system incorporating an inner bag inside an aerosol can, product content inside the bag, and a gas propellant between the can and the inner bag. This new system product enables the use of product content that needs to be separated from contact with the gas, as well as stable spraying at any angle.

2002

Listed on Second Section of Tokyo Stock Exchange

2002 FIFA World Cup Korea/Japan held

2003

Subcontractor for packaging material processing, Matsuya Cellophane Co., Ltd., became a subsidiary

Fujimori PlaChemical Co., Ltd. became a manufacturing subsidiary

Development of high-performance NI Film

NI Film

NI Film (NI-β non-adsorbing low-leaching sealant) is the company's unique high-performance film series that limits interaction with product content. NI-B takes advantage of that property to help maintain quality in cosmetic products in which polyethylene film would adsorb content components. The lineup features products adapted to different content components, and has also been applied to infusion solution bags.

Development of CSP highly hermetic container

CSP

This highly hermetic container, with its integrated main body and lid, can be opened and closed with one touch. Using a specially formulated dry sleeve as the container inner surface enables maintenance of quality even when holding content that requires moisture-proof conditions.

Start of Iraq War

SARS outbreak

Roppongi Hills opened

October

Leap

In 2004, which was the 90th anniversary, Fujimori Kogyo was listed on the First Section of the Tokyo Stock Exchange. The business of the Numata Plant changed for the better, and in a further leap forward, the company promoted “Renewed ZACROS” while establishing a slogan, “strength, benevolence, and inspiration” to share an ideal shape for ten years in the future. In the ten years till 2013, the company repeatedly addressed exciting challenges such as the opening of the Yokohama, Showa and Mie Plants, a change of president and business development in the biopharmaceuticals field, thereby celebrating its 100th anniversary.

Desktop Wallpaper DownloadFor further details, place the cursor over each individual image.

2004

Shares moved to First Section of Tokyo Stock Exchange

Shares moved to First Section of Tokyo Stock Exchange

In celebration of the 90th anniversary, “strength, benevolence, and inspiration” were established as long-term vision and company objectives

Kawasaki Plant closed while Yokohama Plant with laboratory opened

Yokohama Plant

To grow our healthcare and industrial packaging businesses over the long term, we constructed the Yokohama Workplace as a new mother plant equipped with a laboratory, to serve as a replacement for the Kawasaki Workplace. The laboratory features a filling and packaging machinery room housing a wide variety of test and evaluation equipment, an experimental plant, and a prototyping workshop supporting stages from the production and design of prototype models and package testing of products. We have prepared a structure capable of speedily meeting customers' needs, with sales, development and production working as one.

2005

Ohama Plant name changed to Kakegawa Plant

The 2005 World Exposition, Aichi, Japan held

2006

Kanazawa Laboratory, a laboratory to develop cultivation bags and devices, opened

VOC (volatile organic compounds) processing system jointly developed with Nihon Dengi Co., Ltd., Toyota Turbine and Systems Inc. (current Toyota Energy Solutions Inc.), and Toyota Motor Corporation

2007

Showa Plant opened

Showa Plant

Efforts to strengthen our lineup of protective films for polarizing plates and our new product development in the optoelectronics field bore fruit, and our Numata Workplace, a production base for functional materials, was pressed to repeatedly increase production. Demand for layer insulation films used as package substrates was also growing quickly, leading us to construct the Showa Workplace as a new production base.

Established a subsidiary in Hong Kong, China, ZACROS (HONG KONG) CO., LTD.

Professor Shinya Yamanaka of Kyoto University announced success of creating induced pluripotent stem (iPS) cells

2008

All ZACROS Plants received ISO9001 certification

Development of in-spout sealing pouch for liquid food retort pouches

In-spout sealing pouch

Since 2001, the company has supplied customized retort pouches for liquid foods, with enhanced convenience to reduce the burden on nurses in hospitals. In 2008, the company sealed the spout inside the pouch to develop an in-spout sealing pouch that enhances hygiene for patients undergoing gastrostomic feeding.

Bankruptcy of Lehman Brothers

SoftBank Mobile Corp. (current SoftBank Corp.) launched iPhone 3G in Japan

2009

Lay judge system started

Development of infusion solution bag using NI Film

Infusion solution bag

In 1989, the company began manufacturing soft bags made from plastic film for use in intravenous drips. Unlike glass bottle containers, the bags are easy to handle and have contributed to the enhancement of medical work efficiency and the prevention of medical errors. To meet increasingly sophisticated needs, the company adopted non-interacting NI Film to further enhance the product's safety and reliability for use in infusion solution bags.

2010

Head Office moved to Shinjuku-ku, Tokyo

Head Office moved to Shinjuku-ku, Tokyo

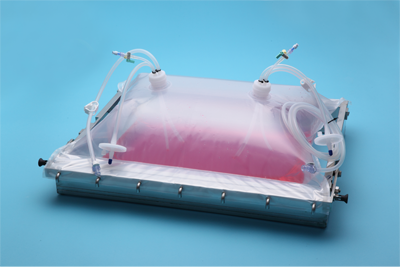

BioPhaS single-use system for biopharmaceutical manufacturing process developed, expanding the business into biopharmaceutical field

BioPhaS

This single-use bag series was developed for the manufacturing processes of biopharmaceuticals, an area that is expected to grow in the future. The company contributes to the advancement of biopharmaceuticals by providing customized services tailored to individual customers' manufacturing processes.

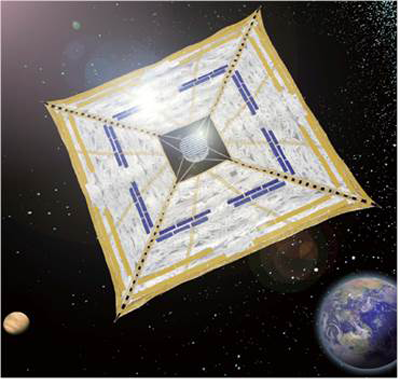

Development of thin polyimide film for IKAROS

Polyimide film for IKAROS

IKAROS was developed by the Japan Aerospace Exploration Agency (JAXA) as a demonstration of a solar sail, a sail that catches sunlight to power spacecraft movement. Creation of the polyimide film used for the sail was initially viewed as difficult, but in collaboration with JAXA, the company resolved numerous issues to achieve a thin polyimide film just 7.5 μm thick.

2011

The 2011 Off the Pacific Coast of Tohoku Earthquake struck

2012

Mie Plant opened

Mie Plant

In January of 2012, we completed construction on the Mie Workplace in the city of Nabari, Mie Prefecture. This site would serve as a new stage in the field of GMP-compliant pharmaceutical and medical packaging. It thoroughly pursued manufacturing management, quality control, and hygiene management meeting the standards of pharmaceutical manufacturing plants, and in 2013 obtained our Company's first manufacturing approval for quasi-drugs and cosmetics. In the following year, 2014, the site obtained certification for ISO 13485, covering quality control for medical devices.

Subsidiary, Zacros America,Inc., founded in the U.S.A.

Zacros America, Inc.

European Council for Nuclear Research (CERN) discovered the Higgs boson

2013

Developed NiP-Σ W121 non-adsorbing low-leaching IV bag

Established a subsidiary in Taiwan, ZACROS TAIWAN Co., Ltd.

ZACROS TAIWAN Co., Ltd.

While establishing a succession of new manufacturing and sales bases in China, North America, and Southeast Asia, we also undertook full-scale construction of overseas manufacturing bases in the information and electronics business. In May 2013, we established a new company in the Southern Taiwan Science Park in Kaohsiung, Taiwan. Construction of a new plant commenced in the following year, 2014. Construction was completed and production began in 2015.

Chairman Akihiko Fujimori and President Eishi Fuyama appointed

November

Tsutsumu (Embrace)

In 2022, Fujimori Kogyo re-shaped its corporate philosophy. Heralding, “ZACROS is committed to realizing a society with genuine happiness through our ‘embracing spirit,’ so that we can be proud of ourselves throughout the following generations,” the company indicated its reason of being. The conventional philosophy of “‘Tsutsumu’ value” is redefined as an “embracing spirit.” This is a precious phrase to share the fact that our business is not only packaging but also something diverse that cannot be done without benevolence and warmth with all stakeholders.

Desktop Wallpaper DownloadFor further details, place the cursor over each individual image.

2014

100th anniversary

Consumption tax rate increased to 8%

2015

Started the sales of a thrombus formation-analysis system, T-TAS, expanding the business into medical equipment field

2016

PT Kingsford Holdings (Indonesia) became a subsidiary jointly with the Mitsui & Co. Group

PT Avesta Continental Pack

PT Indogravure

My Number System started operating

2017

Opened Kobe Satellite Laboratory to promote development of mass culture of cells

Kobe Satellite Laboratory

This site serves a development base for mass culture equipment and systems used in the production of biopharmaceuticals. It carries out development of human cell mass production processes for use in regenerative medicine, employing our BioPhaS single-use product technology. It also engages in development of gene therapy products, along with new single-use products and peripheral equipment such as animal cell culture apparatus.

Tres Cuna

Tres Cuna is an animal cell culture apparatus designed and developed by our Company. In July of 2021, we succeeded in the world's first* propagation of 11 billion human iPS cells while maintaining differentiation capability. *Aggregated culture of human iPS cells, as of July 20, 2021; based on investigation by our Company

2018

Established Fujimori Science and Technology Foundation, general incorporated foundation

2019

Fujimori Science and Technology Foundation changed to public interest incorporated foundation from general incorporated foundation

Fujimori Science and Technology Foundation

This public interest incorporated foundation was established in 2018 to promote science and technology and to contribute to social and economic development. It offers grants for forward-looking, creative research that will lead to the creation of new functions and mechanisms.

Era name changed to Reiwa

Consumption tax rate increased to 10%

2020

T-TAS received U.S. FDA Approval as a medical device

T-TAS

T-TAS is a product born of ongoing research from the early 1990s aimed at exploring new business areas in the pharmaceutical and medical fields. It is an apparatus that performs quantitative measurement of thrombogenicity based on our proprietary measurement principles. A microchannel chip to which biomolecules adhere reproduces the environment inside blood vessels and enables measurement of blood clot formation in the bloodstream.

Head Office moved to Bunkyo-ku, Tokyo

Head Office moved to Bunkyo-ku, Tokyo

COVID-19 pandemic running rampant worldwide

2021

Achieved ultra-large-scale culture of iPS cells using our proprietary cell culture technologies

Olympic and Paralympic Games Tokyo 2020 held

2022

Transition to Prime Market from First Section, following the Tokyo Stock Exchange’s restructuring of market segments

Developed free-standing electrode, ZEF, for next-generation large batteries

Formed J-STAC partnership for domestic production of single-use products for the manufacture of pharmaceuticals

J-STAC

Our Company led the formation of the Japan Single-use Technology Advanced Collaboration, or J-STAC, with the aim of improving on the current high rate of dependency on overseas sources of single-use products required in pharmaceutical manufacturing processes. Through J-STAC, companies that hold product development and manufacturing technologies in Japan cooperate and contribute to the advancement of the pharmaceutical and medical fields through the prompt and stable supply of high-quality single-use products.

2023

Completed construction of a pilot plant for bio-based, marine-biodegradable plastics in Malaysia

Bioplastic demonstration plant

In collaboration with the University of Science, Malaysia and the government-owned public company Standard and Industrial Research Institute of Malaysia (SIRIM), we completed construction of a pilot plant for biomass-derived and marine degradable resins. Taking agricultural waste, residues, and other unused resources as its raw materials, the plant conducts demonstration testing of low-environmental-impact manufacturing processes that use the natural environment's microorganism and insect ecologies in the fermentation, extraction, and refining processes.

Started a new cell culture contract manufacturing business

All nuclear power plants in Germany stopped operating

December

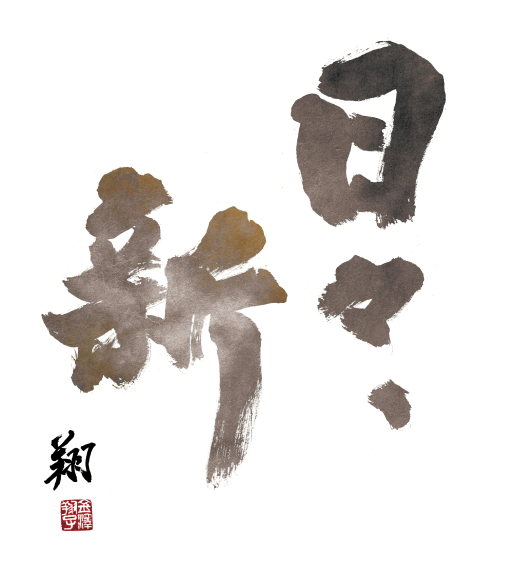

Start Every Day Anew

This phrase means, “Start every day anew,” and is found inGreat Learning, as well-known asthe Analects of Confuciusamong the Four Confucian Classics. Our thought at this very moment, looking back on 110 years, is expressed in “、” (Japanese comma) as our gratitude to people who have spent time together. In addition, the character of “新” represents our determination to make a great leap where, even if the future we will live in is an age of turmoil, we build unique ideas day by day without losing the challenging spirit against difficulties and the unknown.

Desktop Wallpaper Download2024

110th anniversary